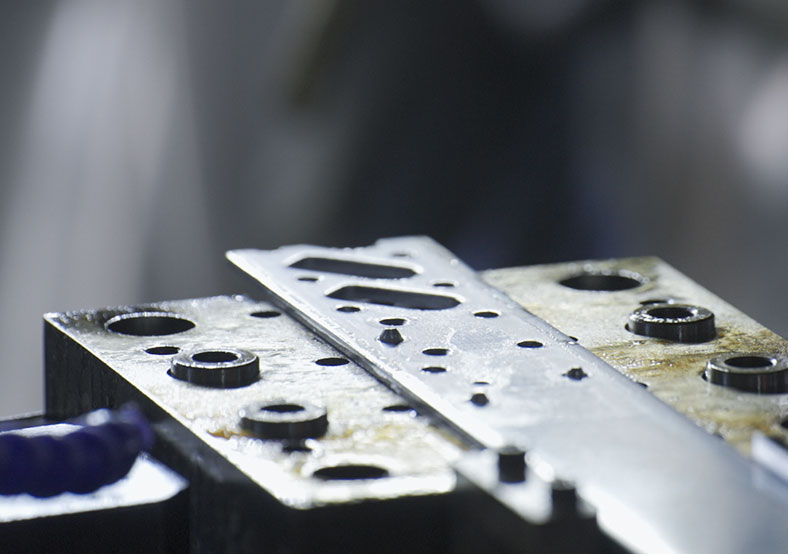

Individualized R&D and Design

OSSDER Clutch has strong individualized product development capabilities, as well as unique key processes and techniques for key components, and has constructed a multi-unit support system for cost control, manufacturing supervision, and efficiency optimization. The company has co-developed and designed with Shaanqi Group, SAIC Group, DCEC, Valeo, SACHS, Schaeffler, Haige, XCMG, and other industries, and has been widely recognized and used.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262