-

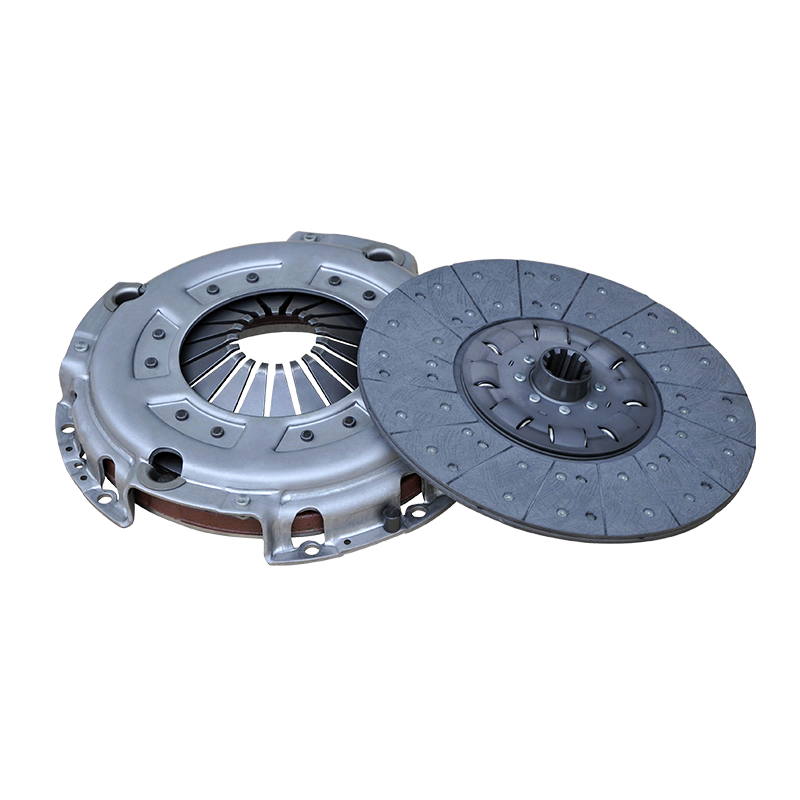

Proper alignment of a 430mm Jinlong Bus Push Clutch Disk Assembly Kit is essential to ensure the smo...

READ MORE -

The auman truck spare parts 430 pull clutch pressure plate assembly kit plays a critical role in ens...

READ MORE -

The 430mm pull type clutch cover assembly kit for FAW Jiefang vehicles plays a critical role in tran...

READ MORE -

Heavy duty truck 430 pull type clutch disc assembly is a crucial component in the drivetrain of heav...

READ MORE -

The Renault Truck Spare Parts 430mm Clutch Assembly Kit plays a pivotal role in maintaining the oper...

READ MORE

Has the surface of the 380 clutch assembly been specially treated to improve wear resistance and corrosion resistance? If so, what surface treatment technologies are used?

In our company, the design, research and development, manufacturing and sales of heavy-duty vehicle clutches is a comprehensive and sophisticated process. Every step embodies the persistent pursuit of technological innovation and strict control of product quality. As a company that focuses on providing finely crafted, cost-effective and trustworthy products to the automotive industry, we are well aware that the clutch is a key component in the automotive transmission system, and its performance is directly related to the safety, reliability and service life of the vehicle. In the manufacturing process of the clutch assembly, especially the 380 clutch assembly, we pay special attention to the use of surface treatment technology to improve the wear resistance and corrosion resistance of the product and ensure that it can maintain a stable working state under harsh working conditions.

1. The necessity of surface treatment

The working environment of the clutch assembly is complex and changeable. It must not only withstand the high torque transmitted by the engine, but also experience frequent friction and wear, and at the same time resist the erosion of external environments such as oil, water, and dust. Therefore, special treatment of the clutch assembly, especially the contact surface of the friction plate and key metal parts, is an important means to improve its comprehensive performance and extend its service life.

2. Specific surface treatment technology used

Ion nitriding:

Ion nitriding is an advanced surface hardening technology. By placing the workpiece in a nitrogen-containing atmosphere under high vacuum or low pressure, the nitrogen ions bombard the workpiece surface using the principle of glow discharge to form a nitride layer. This technology can significantly improve the hardness, wear resistance and fatigue resistance of the clutch component surface while maintaining good toughness. It is one of the key measures to improve the durability of the clutch assembly. Our company has widely adopted this technology on the key friction contact surfaces and support structures of the 380 clutch assembly, effectively improving the overall performance of the product.

Shot Peening:

Shot peening is to form a tiny plastic deformation layer by spraying shot particles onto the surface of the workpiece at high speed, thereby increasing the surface residual compressive stress and fatigue resistance. This technology is particularly important for key force-bearing components in the clutch assembly, such as the pressure plate, flywheel, etc., which can effectively resist stress concentration and fatigue cracks caused by long-term work and extend service life. In the manufacturing process of the 380 clutch assembly, we carefully designed the shot peening process parameters to ensure the best strengthening effect.

Carburizing and Quenching:

Carburizing and quenching is a method of increasing the surface carbon content of steel parts and then quenching them to increase the surface hardness and wear resistance. For the transmission gears and shaft parts in the clutch assembly, we use carburizing and quenching technology, which not only improves the hardness and wear resistance of the parts, but also maintains the good toughness of the core, achieving a good match between strength and toughness.

Anti-Corrosion Coatings:

For the parts of the clutch assembly that may be directly exposed to the corrosive environment, such as the housing and bracket, we apply high-performance anti-corrosion coatings. These coatings are usually made of materials such as epoxy resin, polyurethane or polytetrafluoroethylene, with excellent chemical corrosion resistance and weather resistance, and can effectively isolate corrosive media such as moisture and salt, protecting the substrate from corrosion.

Surface Plating:

In order to further enhance the wear resistance and corrosion resistance of certain parts in the clutch assembly, we also use electroplating, chemical plating and other technologies, such as zinc plating, chrome plating, nickel plating, etc. These coatings not only provide an additional layer of protection, but also improve the appearance and lubrication performance of parts, reduce the friction coefficient, and improve the smoothness and response speed of clutch operation.

As a company that strictly follows German technical standards and produces high-quality products, our company has the industry's leading testing center and a series of advanced testing equipment from Germany, Switzerland, Italy and other countries to ensure that every process and every product can meet the highest standards. Since passing the IATF16949 quality management system certification in 2008, we have always strictly implemented quality control in accordance with the system requirements, and the clutch assembly qualification rate has continued to remain above 99.8%, which is not only a recognition of our technical strength, but also a fulfillment of our commitment to customers.

Under our careful design and manufacturing, the 380 clutch assembly not only uses a variety of advanced surface treatment technologies to improve wear resistance and corrosion resistance, but also relies on the company's strong technical strength and strict quality control system to ensure the excellent performance and reliable quality of the product.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262