-

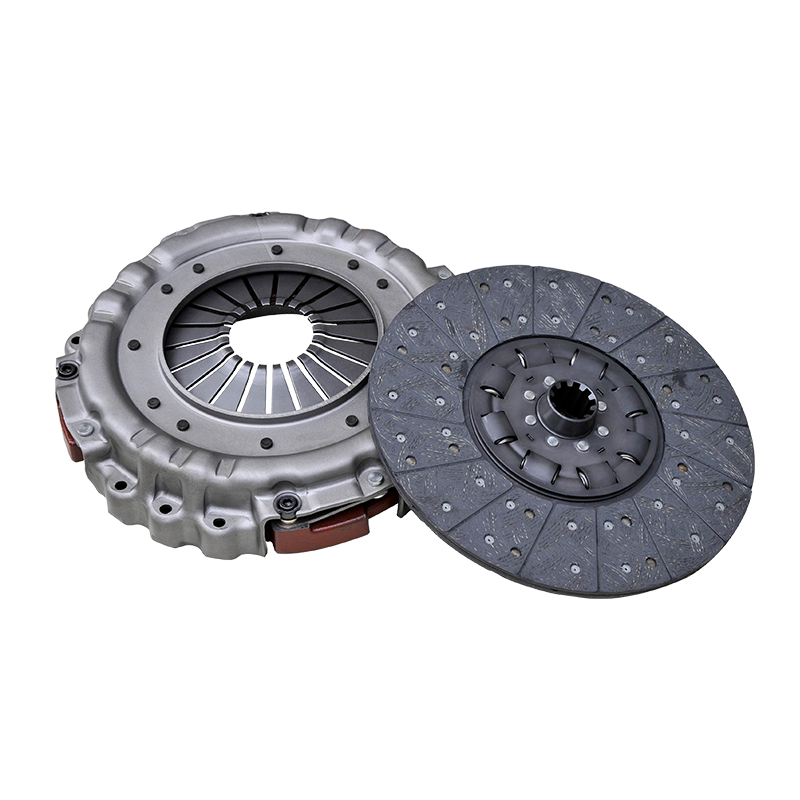

Proper alignment of a 430mm Jinlong Bus Push Clutch Disk Assembly Kit is essential to ensure the smo...

READ MORE -

The auman truck spare parts 430 pull clutch pressure plate assembly kit plays a critical role in ens...

READ MORE -

The 430mm pull type clutch cover assembly kit for FAW Jiefang vehicles plays a critical role in tran...

READ MORE -

Heavy duty truck 430 pull type clutch disc assembly is a crucial component in the drivetrain of heav...

READ MORE -

The Renault Truck Spare Parts 430mm Clutch Assembly Kit plays a pivotal role in maintaining the oper...

READ MORE

How do 395 clutch assembly manufacturers ensure the quality stability of 395 clutch assemblies?

When discussing how 395 clutch assembly manufacturers ensure the quality stability of their products, we have to deeply analyze the technical strength, management system and quality control strategy behind them. As an enterprise focusing on the design, research and development, manufacturing and sales of heavy-duty vehicle clutches, our company not only strictly follows German technical standards, but also integrates the concept of producing high-quality products throughout the entire business process, providing the automotive industry with finely crafted, cost-effective and trustworthy clutch products.

In the technical design and development stage of the clutch assembly, our company has a research and development team composed of senior engineers. They are not only proficient in the working principle and structural design of the clutch, but also keep up with the development trend of the international automotive industry, and constantly introduce new technologies and new materials to improve the performance and reliability of the product. For the 395 clutch assembly, we use advanced friction material formulas to ensure good wear resistance and thermal stability under different working conditions, effectively extending the service life. At the same time, through precise calculation and simulation analysis, the torque transmission efficiency and gear shifting smoothness of the clutch are optimized, vibration and noise are reduced, and the driving experience is improved.

The quality of raw materials is directly related to the performance and stability of the final product. Therefore, we have established a strict supplier audit and management system for raw material procurement, and only cooperate with suppliers who have passed ISO certification, have good reputation and stable supply capacity. For the key components such as steel, friction plates, bearings, etc. required for the 395 clutch assembly, we select internationally renowned brands, such as high-strength alloy steel imported from Germany as the clutch pressure plate material to ensure that it can still maintain good rigidity and toughness under high load. In addition, we also regularly review suppliers to ensure the continued stability of raw material quality.

From mold making to heat treatment, surface treatment, and assembly testing, we have implemented comprehensive and refined management of the production process of the 395 clutch assembly. First of all, advanced CAD/CAM technology is used in mold design and manufacturing to ensure the dimensional accuracy and shape consistency of parts. The heat treatment process follows German standards, and through precise temperature control and time management, the microstructure of the material is optimized, and the hardness and fatigue resistance are improved. The surface treatment adopts environmentally friendly spraying technology, which not only enhances the anti-corrosion performance, but also improves the aesthetics of the product.

During the production process, we introduced intelligent production lines and Internet of Things technology to realize real-time monitoring and automatic collection of production data, ensuring that each process can meet the preset quality standards. In addition, we have established a complete product traceability system. Any product can be traced back to its raw material batch, production personnel, inspection records and other detailed information, which is convenient for quickly locating and solving problems when they occur.

Quality is the lifeline of the product. Since passing the IATF16949 quality management system certification in 2008, our company has always strictly followed the procedures and requirements of the system for quality control management to ensure that every link from design to delivery meets international standards. For the 395 clutch assembly, we have set up a professional testing center in the industry, equipped with a number of advanced testing equipment from Germany, Switzerland, Italy and other countries, including but not limited to material mechanics testing machines, friction and wear testing machines, dynamic fatigue testing machines, etc., to conduct comprehensive and in-depth testing of the products.

The testing content covers multiple key performance indicators such as the clutch's torque transmission capacity, wear resistance, heat resistance, noise level, and gear shifting smoothness, ensuring that each batch of products can meet or even exceed customer expectations. In addition, we also regularly invite third-party testing agencies to conduct product sampling inspections to verify our product quality in a more objective and fair manner.

In addition to the above measures, we have also established a complete customer feedback mechanism and continuous improvement system. By regularly collecting customer feedback, we continuously optimize product design and production processes, solve problems encountered by customers during use, and improve customer satisfaction. At the same time, we provide comprehensive after-sales services, including technical support, maintenance guidance and spare parts supply, to ensure that customers receive timely and effective support during use.

395 Clutch Assembly Manufacturer has built a comprehensive and multi-level quality assurance system through technological innovation, raw material selection, fine production management, strict quality inspection and continuous improvement services to ensure the stability and reliability of product quality. We firmly believe that only by constantly pursuing excellence can we provide customers with valuable product competitive advantages and quality assurance, bring Ausde products into thousands of households, and jointly promote the progress and development of the automotive industry.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262